In the dynamic field of powder coating,

Powder Coat Equipment serves as the cornerstone for achieving high - quality and durable finishes. Whether you're operating in a large - scale industrial environment or a small DIY workshop, having a profound understanding of this equipment is of utmost importance.

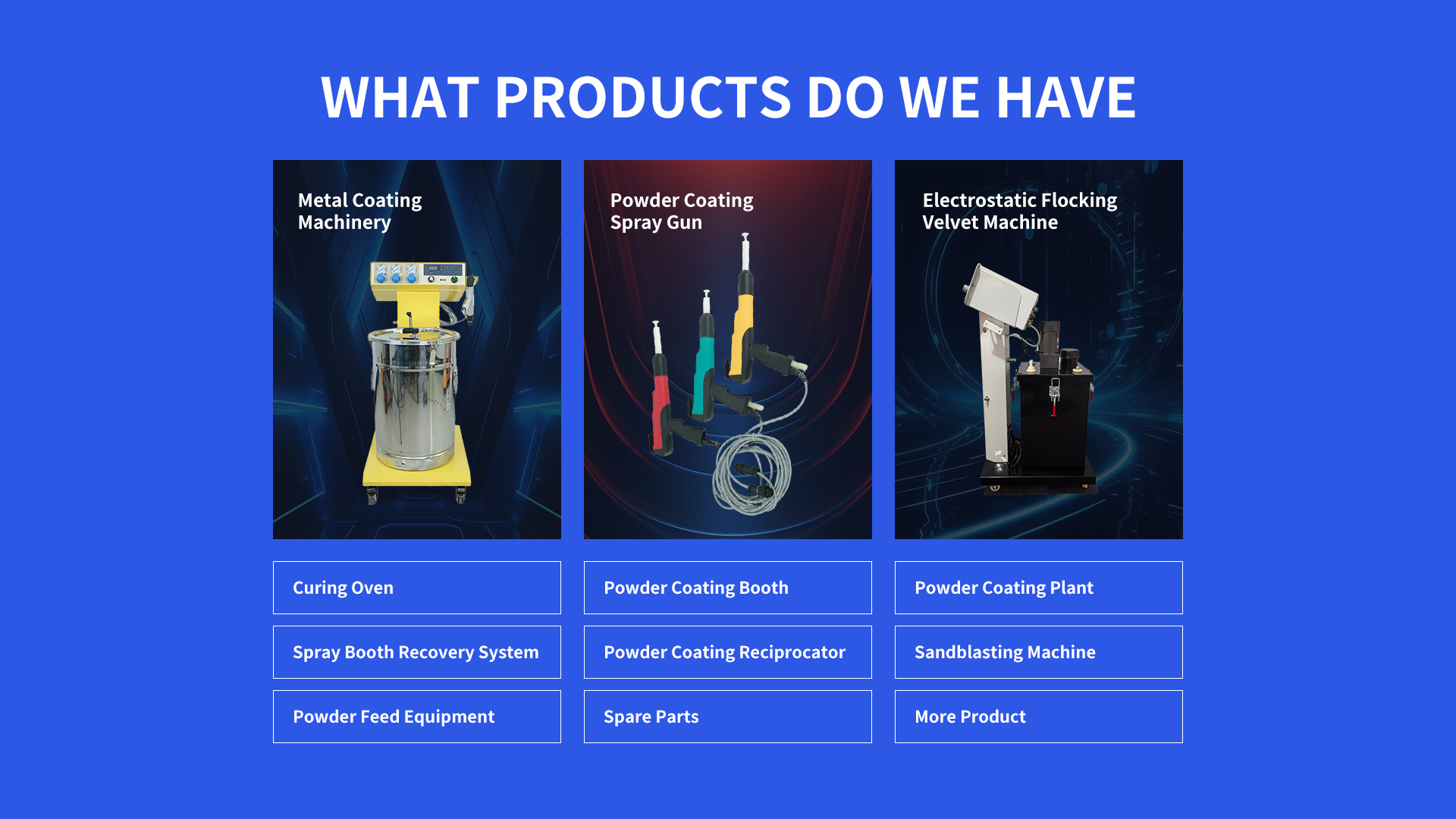

Powder Coat Equipment encompasses a diverse array of tools and machinery specifically designed for the powder coating process.

The fundamental components typically include a powder - spraying gun, a powder - feeding system, an electrostatic charging device, a curing oven, and in certain cases, a booth.

The powder - spraying gun is the primary implement for applying powder onto the workpiece. It comes in various types, such as manual and automatic guns. Manual guns are more suitable for small - scale projects or intricate work, while automatic guns are frequently employed in high - volume production scenarios. The powder - feeding system functions to store and supply powder to the gun. It can be either gravity - fed or pressure - fed, with the latter enabling more precise control over the powder flow.

The electrostatic charging device plays a pivotal role. It imparts an electric charge to the powder, which facilitates the even adhesion of the powder to the grounded workpiece, resulting in a uniform coating. The curing oven is where the transformation occurs. Once the powder is applied, the workpiece is placed in the oven. The heat within the oven melts and fuses the powder, creating a hard and durable finish. When present, the booth contains the over - sprayed powder, maintaining a clean working environment and minimizing powder waste.

Powder Coat Equipment finds extensive applications across multiple industries. In the automotive industry, it is utilized to coat car bodies, rims, and engine components. The powder coating offers excellent corrosion resistance and a sleek appearance. In the furniture manufacturing sector, metal furniture frames and parts are coated to enhance their durability and aesthetic appeal. The construction industry also benefits from powder coat equipment, using it to coat metal building materials such as window frames, handrails, and roofing sheets.

The price of

Powder Coat Equipment can vary significantly. A basic powder - spraying gun and a small powder - feeding system, suitable for DIY enthusiasts or small - scale workshops, can start at around $100 - $500. A mid - range setup, featuring a better - quality gun with adjustable features, a more advanced powder - feeding system, and a small curing oven, may cost between $1000 - $5000. High - end industrial - grade powder coat equipment, equipped with automated powder - reclaim systems, large - capacity curing ovens, and advanced electrostatic control, can cost upwards of $10,000.

Prior to using the equipment, ensure proper assembly and calibration. Connect all components accurately in accordance with the manufacturer's instructions. Prime the powder - feeding system with the appropriate powder. Adjust the electrostatic charge and powder - flow rate based on the workpiece material and the desired coating thickness. When using the powder - spraying gun, hold it perpendicular to the workpiece and move it at a consistent speed. Maintain a distance of approximately 15 - 20 cm between the gun and the workpiece for an even coating. After spraying, place the workpiece in the pre - heated curing oven and set the correct temperature and time according to the powder type.

When choosing

Powder Coat Equipment, take your production needs into consideration. For high - volume production, invest in industrial - grade, automated equipment. For small - scale or DIY projects, a basic or mid - range setup will suffice. Additionally, consider the types of materials you'll be coating. Different materials may necessitate different electrostatic settings and powder - flow rates. Your budget is another crucial factor. Strike a balance between your requirements and the cost to find the most suitable equipment.

Safety is of paramount importance when using

Powder Coat Equipment. Wear appropriate personal protective equipment (PPE), including dust masks to prevent inhalation of powder particles, safety goggles to protect your eyes, and gloves to protect your hands. Work in a well - ventilated area to avoid the accumulation of powder in the air, which can pose a fire or explosion hazard. Regularly inspect the electrical components of the equipment to prevent electrical accidents.

The design of

Powder Coat Equipment is highly rational. The electrostatic charging mechanism ensures efficient powder adhesion, reducing powder waste. The adjustable powder - flow and spray - pattern settings allow for customization according to different workpiece shapes and sizes. The use of high - quality materials in the construction of the equipment ensures its long - term reliability and performance.

Q: What should I do if the powder coating has an uneven thickness?

A: Check the powder - flow rate and the electrostatic charge settings. An inconsistent powder - flow rate or incorrect electrostatic charge can lead to uneven coating. Also, ensure that the gun movement is steady and at the appropriate speed.

A: Yes, but make sure to clean the powder - feeding system thoroughly between different powder types. Different powders may have different particle sizes and chemical compositions, which can impact the coating quality.

Q: How often should I maintain the curing oven?

A: Conduct a monthly inspection of the heating elements, temperature sensors, and insulation of the curing oven. Perform a comprehensive maintenance every 3 - 6 months, including cleaning and replacing worn - out parts.

Q: What if the powder - spraying gun malfunctions?

A: First, check if there are any blockages in the powder - feeding system or the gun nozzle. Also, ensure that the electrostatic charging device is functioning properly. If the problem persists, contact the manufacturer or a professional technician for repair.

A: In some cases, yes. You can upgrade components such as the powder - spraying gun, powder - feeding system, or the electrostatic charging device. However, make sure that the new components are compatible with your existing equipment.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com